Let’s start by breaking down the title of this post. “bright future” implies that past brand color management practices have not delivered desired outcomes – true. “Brand color” refers to the precise color the brand owner is expecting to be reproduced regardless of substrate, print process or geographic location. “Management” is the meat of this post, I will show how to manage the expectations of the brand owner, so as to under promise and over deliver on color reproductions expectations.

Existing Color Systems = Fail

Existing categorization and naming systems have failed our industry and in fact created unmanageable brand owner expectations. Designers work with swatch books that may or may not be in good condition printed on a substrate that probably has no similarity to the substrate the printer will be asked to produce the work on. Worse yet, the designer calls up a “347 Red” in Photoshop and think it looks “just right” on their un-calibrated monitor. At some point downstream a printer will be asked to produce this completely unidentifiable color.

There’s a better way

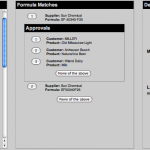

Creation of a database produced on the correct substrate with ink for the desired printing process. In other words, a database of colors that are actually achievable on press. Creating a database of this magnitude is no small endeavor but it’s also no longer a pipe dream. With the support and sponsorship of a client just such a database is now a reality. It’s now easy for supply chain members to request a search of the database for an existing “real” color on the correct substrate with the correct ink.

The solution in a nut shell

A centralized database facilitates accurate communication throughout the supply chain. By utilizing internet technology the exact same color information is made available to brand owners, prepress vendors, printers and ink suppliers. Duplicates can be consolidated with search technologies, thus simplifying paperwork and job preparation. Such a system allows the brand owner to approve a color and then know that prepress vendors, ink suppliers and printers are all using the correct information. The ultimate goal of a centralized database is to provide the brand owner with piece of mind that the color information is being communicated correctly from design to finished product. In addition, ink savings are typically realized because fewer colors need to be maintained and there is less chance of the wrong ones making it to press with the entire supply chain looking at the same information.

While existing color measurement and verification tools “sort of” work there are problems. The lack of systems being able to use a single spectral reference value and then easily share color information (via API or applications programmers interface) back and forth diminishes the effectiveness. By utilizing cloud computing based systems these limitations can be overcome.

Please feel free to contact us for information on how we are delivering the future of brand color management today.

[…] Brand Color Management Has a Bright Future […]