As a leading supplier of wide-format inkjet printers, Mutoh is always on the lookout for innovative ways to make the printing process easier for end users who use their devices. Four years ago, Mutoh approached ColorMetrix for help integrating their new SpectroVue VM-10 color measurement instrument into the print production workflow.

As a leading supplier of wide-format inkjet printers, Mutoh is always on the lookout for innovative ways to make the printing process easier for end users who use their devices. Four years ago, Mutoh approached ColorMetrix for help integrating their new SpectroVue VM-10 color measurement instrument into the print production workflow.

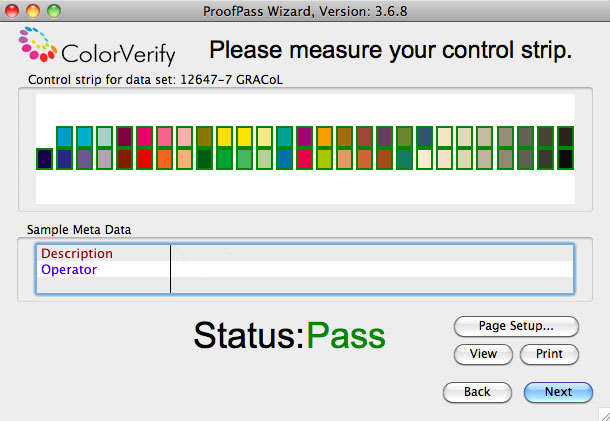

The goal was simple: Provide an easier way for end users to produce consistently high-quality color prints with a high degree of repeatability over time. The result was ColorVerify Pro, which is a rebranded and customized version of our ProofPass technology.

The history of ColorVerify Pro

Mutoh’s SpectroVue VM-10 spectrophotometer is unique in the inkjet market because it can be installed and removed from the printer easily by the end user. The instrument only needs to be installed when measurements are made. This allows one instrument to be shared among several printers in one shop.

The simplest implementation of ColorVerify is embedded in the printer firmware and can be operated from the printer’s front control panel. However, this simple implementation does not allow saving measurements for multiple substrate and print resolution combinations, which limits its usefulness.

Working with Mutoh we built a custom interface to access the SpectroVue VM-10 data stream via the printer’s communications protocols. We called this variation ColorVerify Pro. This made it possible to store multiple color quality baselines in the cloud-based database and check printer performance with any media and print resolutions that had been previously stored.

The problem was there was no good solution

ColorVerify Pro works; perhaps too well. The system can identify a printer that is no longer printing within tolerance to the original baseline. While this is great, the solution involved a great deal of work to get the device back into specification. Typically, the device would need to be linearized and then a new profile would need to be created. In a best case scenario, this often involved at least an hour of operator time.

Users told us that without a simple solution to resolve the out of specification problem, the system would be of little value to them. Inkjet devices have no way to adjust color on the fly like most traditional printing processes. An inkjet printer prints the file you send it. Any alterations to the digital image data occur in the front-end RIP or in Photoshop.

Introducing ColorVerify Pro 2.0

Our goal for ColorVerify Pro 2.0 was to add an “easy button” to the process of color verification and control of Mutoh printers. This starts with the new G7 Calibrator software that is now part of the ColorVerify Pro solution. Instead of relying upon the linearization routines provided by RIP manufacturers, the printer is now calibrated to a known gray balance standard before any printing begins.

The gray balance calibration process, which conforms with CGATS TR015-2013, occurs entirely within the ColorVerify solution. While this adds a few steps to the wizard-based software application, the results are well worth the effort. In fact, the time that the added steps take is typically offset by no longer needing to linearize the device. Once gray balance that is in conformance with TR015-2013 is achieved, this becomes the color baseline for the media and print resolution.

Generated curve data can be imported or hand entered into a RIP. Adobe curve files can also be used to adjust images prior to sending them to a printer with a RIP that may not support curve adjustment.

Ongoing verification is your easy button

Each time a verification target is printed and measured, a new gray balance curve is generated. One of the unique features of the system is that this iterated curve will always be as good or better than the existing curve. So when the desired print specification is no longer being achieved, it’s a matter of updating the gray balance curve to the most recent iteration. Then another verification target can be printed, measured and compared to the print specification. If the target passes, the process is complete. If not, the next iterated curve is used and the process repeated until the device is back in specification.

While the process may sound complicated, a simple wizard-driven software application guides the user through the entire process from start to finish.

ColorVerify Pro 2.0 is the foundation for so much more

While the results of ColorVerify Pro 2.0 will be sufficient for many users, those wishing to take their color management process to the next level will be well-positioned to do so. By starting from a known gray balanced state, the process of creating ICC color profiles is made much easier.

The creation of an accurate ICC profile depends upon the gray patches produced in a typical color management target. While the math in most profile creation software can adjust for those patches being out of balance, it works better when they start in balance. The entire system is less stressed from the beginning and the generation of a valid profile is more likely on the first try.

Finally, because the profiles are generated after a known gray balance state is achieved, it’s possible to continue using those profiles even after an iterated curve is used to return the printer to that known state. In fact, there should be no reason to recreate profiles unless media or print conditions are changed. When color problems occur, users can always start by printing a verification target and installing an iterated curve if the ColorVerify Pro 2.0 system indicates that is your corrective action.

[pl_button type=”success” link=”https://www.sgia.org/journal/2014/sgia-journal-graphic-edition-julyaugust-2014/leveraging-g7-based-calibration-effective” size=”large” target=”blank”]Click here to read an article in SGIA Journal by G7 Calibrator developer Chris Brown[/pl_button]

[pl_button type=”success” link=” https://colormetrix.com/contact” size=”large” target=”blank”]Click here to contact our sales team[/pl_button]